Angora goats produce a fiber called Mohair. It is one of the warmest natural fibers in the world. Mohair is not to be confused with Angora which comes from Rabbits of the same region of Ankara, Turkey.

Angora goats produce a fiber called Mohair. It is one of the warmest natural fibers in the world. Mohair is not to be confused with Angora which comes from Rabbits of the same region of Ankara, Turkey.

Turning mohair into a finished, usable product takes about 7 steps. Luckily, the fiber is sellable in all of its forms. Even the animals themselves can make you a profit with the sale of offspring.

All of the phases of wool processing can be done by hand on the homestead. However, it is a labor-intensive job. For the first 3 years, I processed our wool by hand and found that it wasn’t worth the effort for what I could charge.

In my next post, I will discuss the pros and cons of sending fiber to a mill to be processed.

Even if you do decide to go with a mill, I encourage you to try the process by hand at least once. It is incredibly interesting and will help you better understand your product.

- Shearing

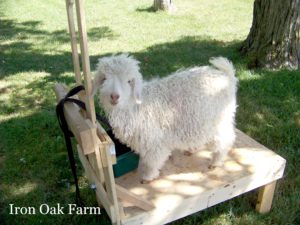

Before you begin processing the fiber, you must take it off the animal.

Before you begin processing the fiber, you must take it off the animal.

Angora goats must be shorn twice a year. We shear in September and March. An adult goat will produce between 8-16 pounds of fiber per year.

Kid mohair is worth about twice as much as adult due to its softness.

You can hire people to come and shear your goats, but the most cost-effective way is to do it yourself.

You can hire people to come and shear your goats, but the most cost-effective way is to do it yourself.

We’ve found the best way to shear our goats is in a stanchion. This is a stand that holds the goat’s head in place and allows it to have a treat as an incentive to sit still. In my opinion, if you can trim your goat’s hooves, you can shear them.

When I first started, it took me 3 hours to shear our goat kid. Now I can do an adult in about 15-20 minutes, nick free and with very few second cuts (where you run the blade over already shorn wool and get an undesirable short lock). It takes patience and practice but it’s completely do-able.

You will also need shears designed for wool producing animals. Human hair cutting shears and even shears meant for dogs will not work. The teeth on wool shears are set wider apart and allow the lanolin coated fiber to go between.

You will also need shears designed for wool producing animals. Human hair cutting shears and even shears meant for dogs will not work. The teeth on wool shears are set wider apart and allow the lanolin coated fiber to go between.

We use the Lister Star Clipper Shears with the with the fine tooth blade. They run around $230 but are well worth the investment.

From this point on, the fiber is a saleable product. The mohair at this point is described as unwashed locks or raw fleece.

Fiber artists are often interested in purchasing a whole fleece and processing it themselves. This is especially true if they want to blend it with another wool like Alpaca, Shetland, Merino etc.

Raw fiber usually brings the least amount of profit.

- Washing the Fiber

The mohair must be soaked in hot soapy water to remove the lanolin and rinsed in hot water for several cycles without disturbing the fiber too much or you risk felting the wool (creating a giant matte).

The mohair must be soaked in hot soapy water to remove the lanolin and rinsed in hot water for several cycles without disturbing the fiber too much or you risk felting the wool (creating a giant matte).

It’s a stinky-messy process and I found that I would empty our home hot water tank getting the fiber clean. You can also wash wool in the washing machine, but the process is pretty similar.

- Selling locks

At this point, the mohair can be sold as Washed Fiber or Locks.

Clean Locks are washed fiber with the vegetation matter picked/removed. Spinners use this to create art yarns with an interesting texture.

- Carding

Once the wool is washed and air dried it can be carded. Carding can happen before or after dying. Some people dye the fiber then mix it using the carders to create certain effects.

Once the wool is washed and air dried it can be carded. Carding can happen before or after dying. Some people dye the fiber then mix it using the carders to create certain effects.

Carding serves two purposes. It removes the debris/vegetation from the wool and it aligns the fibers so that it is ready for spinning.

To card, the fiber must be combed several times and picked through until each strand is smooth.

It can then be removed and rolled into a rollag to be used in spinning.

It can then be removed and rolled into a rollag to be used in spinning.

- Dying Fiber

While Mohair is beautiful in its natural cream/off-white color, dying can be fun and creates a more interesting product for your customers. This is where you can really get creative.

I use Jacquard Dyes meant for natural fibers. There are endless techniques for dying and blending fiber, so without getting too detailed, simply know that this is where a lot of creativity can happen and you can work on a style that speaks for your brand.

I use Jacquard Dyes meant for natural fibers. There are endless techniques for dying and blending fiber, so without getting too detailed, simply know that this is where a lot of creativity can happen and you can work on a style that speaks for your brand.

- Spinning

The art of spinning is really becoming popular. I find that I sell just as much roving (mill processed fiber ready to be spun) as I do finished yarn.

The art of spinning is really becoming popular. I find that I sell just as much roving (mill processed fiber ready to be spun) as I do finished yarn.

If you’ve decided to raise goats it might be a good idea to learn the art of spinning. Taking your homegrown product all the way from goat to skein of yarn is not only extremely satisfying but will get you the most profit from your Mohair.

Check back in my next post where we go over the benefits of sending your Mohair to a Wool Mill.