Extending the growing season by adding a greenhouse has become an important factor to consider for our small farmer’s market business. After feeling out the need for produce most requested in local farmer’s markets, we noticed one key factor – the early bird gets the worm.

The first produce out the gate was eagerly purchased because other vendors weren’t able to supply it…yet. While many of us waited for things to ripen, a strong demand was there begging to be filled.

So, my husband and I asked ourselves, what could we do to capture some of that business and add more functionality to our 25-acre farm? Our answer was to add a greenhouse.

In the past, my husband and I have used low tunnels to get a jump on the season. They worked well for smaller plants but they were never something that was quick or simple to erect in a strong North Dakota wind.

For a late season garden, the low tunnels were less effective, especially in the case of taller plants. One year we lost an entire crop of tomatoes. Plants loaded with beautiful green fruit on the vines never stood a chance against the hard-freeze. It was heartbreaking.

For the most part, our frost protection methods have worked well for our main garden. Tarps, sheets, and even plastic garbage bags will always be reliable tools. However, they are not effective in extending the growing season. Up to this point, we could only hope, pray and cross our fingers Mother Nature would be kind to us. That was just not enough.

FACTORS IN CHOOSING A GREENHOUSE

It was mind-boggling to realize the sheer number and types of greenhouses that are available. From hot houses and hoop houses with their plastic sheeting walls to glass pane houses and twin wall polycarbonate greenhouses, we had many to choose from.

It all boiled down to what would work best for our climate, winds and intended use. Here are a few factors we had to consider when choosing a greenhouse that was right for our farm.

3 SEASON OR ALL SEASON?

As our previous home had a south facing “greenhouse” room my husband and I were pretty versed on what we wanted. An all-season greenhouse would require a heat source living this far north…so that was out of the question.

On the other hand, a 3-season greenhouse would work well to extend the growing season. It should require little more than passive solar heat to keep it functioning well during the early spring and into the late fall.

INSULATION PROPERTIES

Knowing whichever type of greenhouse we would finally settle upon, it would have to retain as much of the sun’s heat as possible. Especially, since we intended to use the space to start plants early and extend them later.

Our experience with plastic sheeting was promising as we had been using this method to create a covered, enclosed pen for our chickens. During the winter this kept snow out, light and heat from the sun in. But, it was limited in the amount of heat it could retain and it could be easily punctured or torn.

Glass had some of the very same issues. Single panes were not as insulative, fragile in the cold and possibly dangerous if it were to shatter.

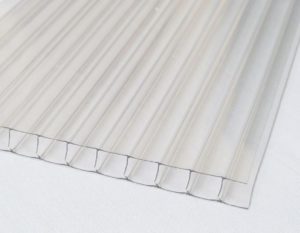

Twin wall polycarbonate panels appeared to be the obvious and best choice. The panels have been touted to be virtually indestructible. Not only does the twin wall construction add strength to the panels, there were a few other added benefits.

Twin wall panels have encapsulated air spaces which offer another level of insulation. These spaces also refract and diffuse light throughout the greenhouse while a UV coating helps protect plants from becoming scorched in the high summer sun.

SNOW LOAD

This was another HUGE factor in choosing a strong polycarbonate panel greenhouse. North Dakota is known for its blizzards, bitter temperatures, occasional hail and insane amounts of snow.

Unless a greenhouse was built like a house, we were concerned that the structure needed to resist the weight of snow as well as deflect snow. In other words, the shape had to add strength while allowing the snow to slide right off.

With a little research, we found that polycarbonate houses are generally very angular. While the overall design is still good, it wouldn’t allow as much snow to deflect off the structure as curved sides would. The search was on for a curvy, peaked, almost Quonset style greenhouse.

WIND RESISTANCE

In much the same way our new greenhouse had to withstand snow, it also had to stand up to strong winds. Flat sides are virtual sails when a strong blizzard force wind hits.

For our purposes, curved sides would allow wind to flow easier over the structure. In theory, this would allow greater aerodynamics and less stress on the greenhouse.

Not only did we have to take the walls into account but also the strength of the framing structure. The greenhouse we were seeking also had to have a sturdy foundation rail, side reinforcement, and doors to close it securely from damaging wind gusts.

FLOORING, FOUNDATION & ANCHORING

While some may choose to erect a greenhouse with a solid floor, here on our 25 Acres we wanted the floor to be our growing medium. Because of this reason we also knew that anchoring the frame would be tricky but essential.

Frozen ground heaving, brisk winds blowing, we’ve got it all here in North Dakota. Various anchoring options are available, many consisting of cable systems which secure to in-ground hooks. My husband has considered the idea of bolting a greenhouse frame onto a poured cement foundation similar to that of a house…just on a smaller scale.

For those who may not want a soil floor, you may wish to consider other options. A poured cement slab being the cleanest and most expensive option. This flooring medium is typically reserved for a professional scale greenhouse, fitted with floor drains or grates.

Wooden floors have also been utilized but tend to rot or warp with the high moisture and humidity. Crushed rock is a great mid-range option. Not only does the stone retain the sun’s heat, water drainage is outstanding.

VENTILATION

Summertime greenhouses can get hot, hot, hot! Ventilation on something such as a plastic sheeted house typically receives air flow by lifting the base of the sheeting up or by opening the doorway.

Polycarbonate and glass greenhouses require vents installed within the frame of the structure. Ideally, these vents will be located along the roofline where the heat can easily rise out of the space. This would be a ‘must have’ in the greenhouse we were looking for.

If electric is available, fans can also be utilized to circulate warm air. This could effectively help cool or distribute heated air throughout the entirety of the greenhouse. That leads us to the next factor to consider.

UTILITIES

Knowing that my husband and I did not want to add electric utilities to our greenhouse gave us one less decision to make. Additions such as solar-powered lighting should work well enough to allow us to see when daylight is in short supply. Perhaps with a little research, we will find an affordable solar option to run a few fans also.

A utility imperative to keeping plants healthy in the greenhouse is water. You can’t keep plants without it. No need to have running water directly plumbed into space. A garden hose hooked up to a sprayer works just as well. Luckily for us, we have spigots located throughout the property.

If a water faucet isn’t nearby, various other methods of watering can also work. Gravity or pump run, cisterns could be filled with delivered water during the warmer months. Depending on the shape and location of your greenhouse you may even consider a rainwater collection system.

SIZE

Finally, and this is an important one, we had to consider the amount of growing space we desired. Super small greenhouses are cute but we wanted more growing functionality than an 8 ft x 8 ft space could give us. Many of the plants we intend to grow would also be grown in the main garden. The ones in the greenhouse would simply be started sooner and harvested earlier.

One issue with a larger span greenhouse wasn’t just the overall price increase. Structurally, the larger the greenhouse, the more susceptible it can be to snow load or wind damage. Because of this, we wanted to find a nice, mid-sized polycarbonate panel building that would give us a decent amount of in-ground garden space while maintaining its integrity.

OUR FINAL CHOICE

After much research and price checking, we decided upon an 8 ft x 20 ft polycarbonate panel greenhouse. At just over $2200 the Palram Bella Hobby Greenhouse was one investment we hope will last for many years.

The bell shape of the structure allows snow to easily slide off the outer walls while making the greenhouse sturdy enough to withstand 60+ mph winds. The polycarbonate walls were the key to making this the perfect choice for us.

With Palram’s 5 yr limited warranty and quality construction, it helps make the financial investment a little less frightening. And, although we won’t be able to put this gem up until spring, it already has me over the moon excited!

For more details on this beautiful greenhouse, CLICK HERE! The listed retail price on this product is about $3000, however, it can be found via Amazon, Home Depot or even Walmart for between $2200-$2500.

Spring 2018 here we come!

#LifeOn25Acres